ISO FITS AND TOLERANCES CHART ISO

Simply Bearings Ltd - Providing ISO Limits and fits for your bearing and bushing needs.Note: Hole based fits should be preferred

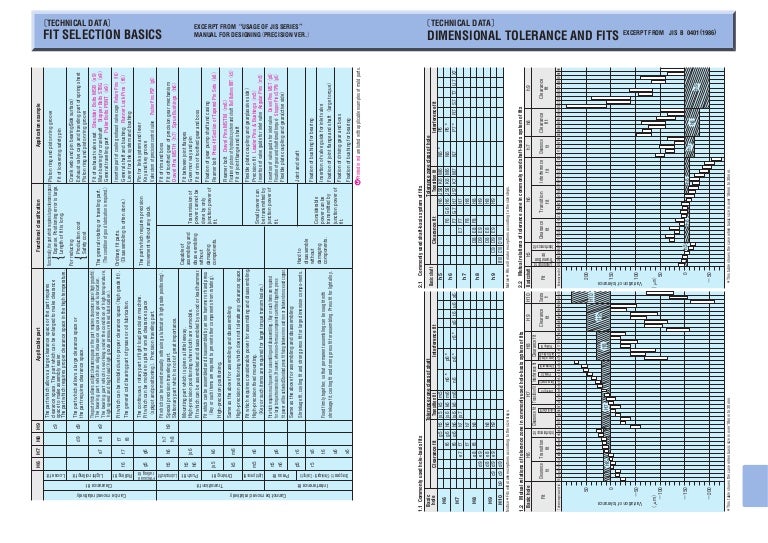

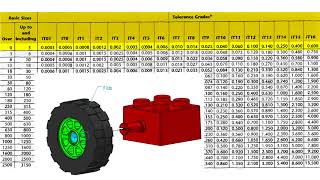

ex: 25 H11/c11 or separated with a dash ex: 25 H11-c11 Fits are either based on the hole feature or the shaft feature. ex: 25 H11 or 25 c11 A fit is defined by the basic size followed by the tolerance of each component. A feature tolerance is defined by the basic size followed by the tolerance designation.GUIDELINES‐‐‐TRANSITION FITS Combinations recommended in BOL ISO Hole & Shaft tolerances/limits - Roy Mec Fixed plugs, driven bushings, armatures of electric motors on shafts, gear rims, flushed bolts. Mounting of fits using pressing and light force. The nut and bolt deviations and tolerance zones are illustrated here H7/m6,H7/n6, M8/h6, N8/h7,N7/h6 Fixed fits with negligible clearances or small interferences. Generally 6H/6g are regarded as medium fit. 5H, 6H, 6G and 7H for internal threads, and 4H, 6g, 6e, 8g for external threads. Nominal Shaft Sizes (mm) over BS 3643 Pt1 and Pt2: 2007 specifies the fundamental deviations and tolerances for e.g. Tolerances are written as a combination of a tolerance band, signified by an alphabetic letter (E, G, e, f, g or h, with uppercase letters signifying internal threads, and lowercase signifying external), and a tolerance class, signified by a number Chart limit and fit | ISO tolerances for holes| ISO tolerance for shafts | ISO Tolerances for Holes (ISO 286-2) Nominal hole sizes (mm) over 3. The information below can be used to calculate the values of thread tolerances defined by ISO 965/1. Preferred tolerance grade ISO 286 International Tolerance Grade ISO Metric Thread Tolerance Tables. Enter your desired preferred tolerance grade and the nomial size.

ISO FITS AND TOLERANCES CHART PLUS

The following Engineering calculator will show the plus and minus tolerance for the specific ISO 286 hole tolerance data. Application of ISO fitting and limit chart, H7.g Preferred Tolerance Grade Zones ISO 286 **** International Tolerance Grades For more exhaustive fastener tolerance. Related Mechanical Tolerance Design Data. These size charts do not compensate position or other GD&T location tolerances. The following ISO Tolerance Chart for bolts and holes per ISO 286. The usage of these tolerances is advised for economic reasons Mechanical Tolerance Standards Menu. Preferred fits and tolerance table for hole and shaft basis systems which are given in ISO 286-1 (2010) and ANSI B4.2-1978 standards. Note for the tolerance bands which can be either side of zero, (J,K,N,j ) The diagrams provided with the table clearly show calculation needed.e.g.Based on standard tolerances and limit deviations in accordance with ISO 286

0 kommentar(er)

0 kommentar(er)